Waveguides are some of the highest performing interconnect and passive components that can be used in RF systems. A waveguide efficiently transfers RF signal energy in a given band and can often handle extremely high-power levels due to a waveguide’s mostly conductive material (metal) construction. The main difference between a waveguide and a transmission line is the type of wave mode that is carried. A waveguide is typically hollow where a transmission line generally has an internal conductive structure necessary to achieve a desired transmission mode. Hence, a transmission line using multiple conductors to support a transverse electromagnetic (TEM) mode wave where a waveguide supports a transverse electric and/or transverse magnetic (TM) mode wave, which amounts to electromagnetic waves “bouncing” off of the inner walls of the waveguide.

For a waveguide, the conductive inner walls function as guide to the wavefront injected into the waveguide and exhibit distributed inductance and capacitance as a function of the internal geometry of the waveguide. This results in a wave impedance, as opposed to a transmission line characteristic impedance. For this reason, the characteristics of the waveguide internal wall are the most critical for electrical performance, which is why waveguides are often coated with precious metals that prevent corrosion and enhance surface finish.

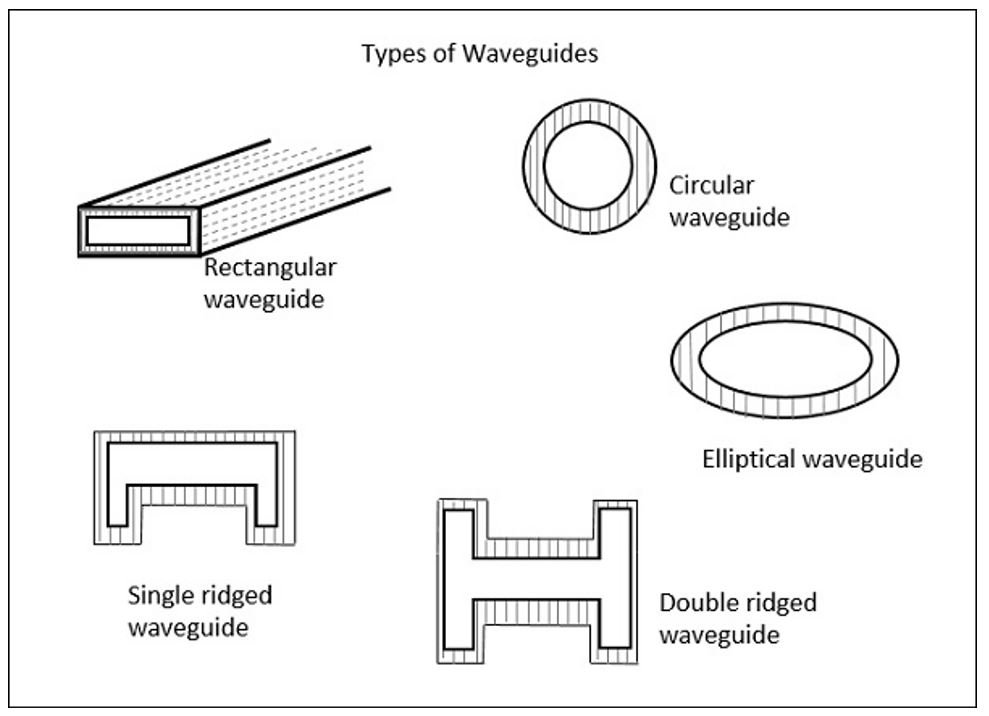

There are several varieties of waveguide types, defined by the internal cross-sectional shape of the waveguide. These main types are rectangular, circular, elliptical, finline, parallel plate, substrate-integrated, single-ridged, and double-ridged. The most common waveguides used in RF systems are rectangular, circular, elliptica, single-ridged, and double-ridged, with rectangular waveguides being the most common.

Both single-ridged and double-ridged waveguide are essentially rectangular waveguide with capacitive loading in the center of the broad wall of the waveguide. The benefits of an added ridge to the waveguide are that ridged waveguide tend to exhibit much lower cut-off frequency of the fundamental mode, an increased frequency of the higher order mode, and allow for certain waveguide components to be more readily fabricated than with typical rectangular waveguide. However, ridged waveguide tend to exhibit higher losses than rectangular waveguide. Moreover, ridged waveguide tend to also suffer less power handling capability and ridged waveguide modes are not as readily analytically determined as with rectangular waveguide.

There are also flexible versions of both rectangular and elliptical waveguide. Flexible waveguide are generally some type of interlocked corrugated structures with features that are small enough that they don’t substantially interfere with the fundamental mode of the waveguide. Flexible waveguide, though often useful or necessary in some applications, tend to exhibit lower performance than rigid waveguide, but do generally offer some weight savings.

Circular and elliptical waveguide are considered more specialized than rectangular waveguide. However, there are some applications, such as with rotary joints, where a circular waveguide is very useful. Circular waveguides tend to by physically larger than rectangular waveguide, which could also be helpful for extremely high frequency applications were a rectangular waveguide may be so minute that it is expensive to manufacture and ensure decent tolerance. A circular waveguide may also exhibit lower attenuation per unit length than rectangular waveguides and be better suited to long distance applications. Also, circular waveguide are able to guide circularly polarized waves, as well as linearly vertical and horizontal polarized waves simultaneously.